14 October 2016

From buses through to intercity trains: The inertia dynamometer now installed in Essen by TÜV NORD monitors the brakes of trucks and railway vehicles.

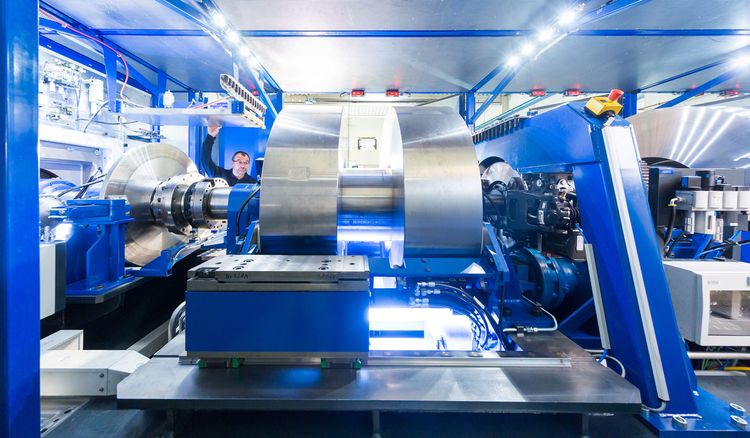

New dimensions: The test rig tips the scales at 80 tonnes. It makes it possible to test not only the brakes of commercial vehicles but also those of rail vehicles, such as the high-speed intercity trains of Deutsche Bahn.

© TÜV NORDPeter Artelt (l) and Heiko Böker show the brake pad for a railway vehicle brake on the test rig.

When brakes are tested in the Institute of Vehicle Technology and Mobility of TÜV NORD, the procedure bears no resemblance to the testing of vehicle brakes on a chassis dynamometer in the context of periodic vehicle testing. The tests are instead concerned with, for instance, type approval for commercial vehicle brakes or brake pads. For instance, wheel brakes can be set up on the test rig along with a complete lorry axle and “abused”. Brakes for road vehicles have been tested in Essen for over 30 years.

The new test rig completes a set already consisting of an inertia dynamometer for commercial vehicles and two more for passenger cars. TÜV NORD has invested some € 3 million in the test rig. As General Manager Dr Robert Plank makes clear: “We aren’t just investing in new business fields abroad. We’re also enabling our regional sales business here in Germany and our Institute for Vehicle Technology to continue to contribute at a high level to the business success of our company.”

© TÜV NORDThree heavy-duty transporters were used to deliver the 80-tonne colossus.

On the dimensions in railway technology: Railway vehicle wheels have a diameter of up to 1.60 metres and each of them weighs more than 600 kilograms. What’s more, the test rig motor produces an output of 700 kW and allows for a maximum of 2,850 revolutions per minute. For an ICE wheel with a diameter of 89 centimetres, for example, this means a speed of about 470 kilometres per hour. The colossus weighs a whopping 80 tonnes, which is why it had to be placed on ten piles driven eleven metres deep into the ground.

With such dimensions, speeds and forces in play, particular attention has to be paid to the operational safety issue. The explosive part of the test rig is thus equipped with reinforcing steel plates that are centimetres thick and weigh many tonnes. As Carsten Winkelbach, Director of the Institute, explains: “For 2017 we’re aiming to get our test rig approved by the UIC, the International Union of Railways. If we succeed, we’ll be the seventh site in the world to operate an officially approved, independently operated inertia dynamometer for friction lining homologation in the railway sector.”