13 June 2019

Flying, swimming, climbing, eating without being eaten – since the beginning of time, living organisms have developed successful strategies in order to adapt to their environment. So it is logical and clear that inventive engineers try to transfer such processes and mechanisms to the field of engineering and technology. The inventor of hook and loop tape, for example, was inspired by burrs from hooked bristlegrass. And bionics is also gaining ever more ground in the area of robotics.

The grey trunk cautiously reaches for the apple on the floor of the box, lifts it up carefully and passes it to Angela Merkel, who takes it with obvious pleasure. But a peanut is not offered in exchange. For in fact the German Chancellor did not come into contact with a real elephant at the Hannover Fair in 2010. The trunk was in fact a robotic arm, whose manufacturer Festo was inspired by a natural model. The idea behind it: apart from the human hand, there is hardly any gripping organ in nature as multifunctional as an elephant’s trunk. And in contrast to the human hand, a trunk does not contain any bone structure, but 40,000 muscles. This makes it enormously mobile and flexible and means that the elephant can use the considerable strength of its elongated nose very delicately in order to pick up even the smallest objects. A principle from which the developers at Festo wanted to learn. The challenge: the robot arm should be as yielding as possible, in order not to injure human beings, and at the same time it should be stiff enough to perform its tasks. The solution found by the engineers: polyamide instead of metal, compressed air instead of rigid construction. Combined with a special structure, this brings new advantages which real elephants could only dream of: if an object is actually beyond reach, a puff of compressed air is sufficient to elongate the trunk from 70 to 110 centimetres in a fraction of a second.

Biology + Engineering = Bionics

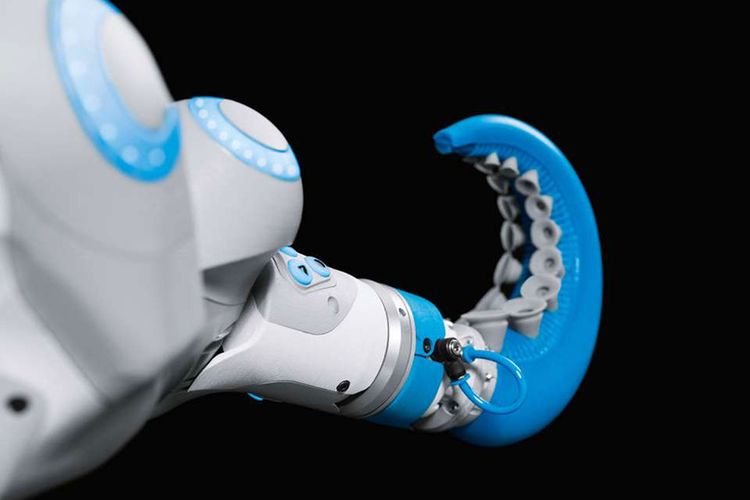

In the meantime, Festo has developed the robot arm further over several generations. And it is by no means the only project of the automation experts from Baden-Württemberg which follows bionic principles. Bionics, a new concept created from the words biology and electronics, means systematic transfer of mechanisms and processes from nature to the worlds of engineering and technology. For example, the “FlexShapeGripper” is based on the tongue of a chameleon, while the “TentacleGripper” is inspired by an octopus tentacle. This gripper could give older or disabled people a hand with everyday life in future. And the gripper which the robot arm used in order to pass the apple to the German Chancellor is also based on a living creature: the so-called “FinGripper“ imitates the tail fin of a bony fish, or teleost. The gripper is constructed in such a way that it curves and curls round a pressure point like the fin, and so adapts to the object which it wants to grip. The force is then distributed over a wider area – and according to the manufacturer, the greater the contact pressure, the more effectively this occurs. This means that the gripper can even pick up sensitive objects such as fruits, light bulbs or chocolate eggs without crushing them. Festo has told us that the gripper, now prepared for mass production, is already being used in the food industry in order to sort fruit and vegetables.

© Festo AG & Co. KG, alle Rechte vorbehaltenThe TentacleGripper adopts the mechanisms of an octopus arm.

InspiRat – Inspired by rats

These projects came into being during within the “Bionic Learning Network”, instigated by Festo in 2006. Within the network, Festo as a manufacturing company works with various research institutions from Germany, Austria, Norway and the Netherlands. One of these partners is the Technical University in Ilmenau.

Here, in the specialist area of biomechatronics, researchers are working on the development and improvement of mechatronic products and processes, using knowledge gained from biology and medicine. “Engineers have always taken some of their ideas from nature”, says Hartmut Witte, head of the Biomechatronics Department. In his time, Otto Lilienthal, for example, observed birds, then optimised his flying machine and so was the first human being to become airborne. “And bionics is a method which helps to promote this ability to form associations and to systematise them and to put the stimulus for the development of technical products onto a broader footing”, explains Witte. So bionics is not intended to invent technology afresh, but to find nature-based solutions to technical problems which so far have not been capable of resolution by conventional methods.

In order to achieve this, experts from the different specialist areas pool their knowledge, for bionics always requires interdisciplinary cooperation. Together with biologists from Jena University and the Ilmenau robotics company Tetra, the engineers have for example constructed a climbing robot within the “InspiRat” project. The “ratnic”, which is both small and light, can climb to places where up to now it has been too cramped or too steep for access by human beings and existing service robots. For example, the ratnic could crawl through cable ducts in order to search for cable damage with a miniature camera.

Analogy instead of mimicry

The ratnic robot – which is built of aluminium tubes, springs and pulleys – does not really look like the sentient creature from which it takes its name. And this is quite normal and logical: the rule of thumb is that if bionics are involved, they cannot be seen from the outside”, explains Witte. For the bionics engineers want to transfer the principle of movement of the rat to a robot system, and not to copy nature one to one. For this, the climbing skills of the rat were first thoroughly explored by the zoologists from Jena University, using high/speed X-ray apparatus, and allowing rats to scramble upwards In front of it. Although the researchers working around the biologist Prof. Dr. Martin S. Fischer have been investigatig the movement of small mammals for many years, this X-ray procedure led to new and surprising revelations. “In the field of research, we assumed for a long time that the trunk muscles did the most work when rats were climbing. But we have established that only 15 per cent of the power comes from the trunk. The remaining 85 per cent is generated by the muscles of the extremities”, explains biomechatronics engineer Witte.

© Tetra GmbH IlmenauThe “robot rat” reaches places which people cannot.

Therefore the robot also does not have a trunk or torso in the real meaning of the word. It rather consists of a smaller front section and larger rear section, which are connected by means of a movable backbone of aluminium rods. While the grippers of the rear part of the body hold onto a vertical tube, the front part pushes upwards and holds fast before the rear part follows on. As far as robotics is concerned, this combination of bionic functional principles and the associated lightweight construction represents a true leap forward. “Before we started the project, the lightest robot on the market weighed 35 kilograms”, says Hartmut Witte. But the “ratnic” weighs in at just 1.1 kilos and therefore according to its makers consumes 75 per cent less energy than a conventional robot.

Sticky as a beetle’s foot

The biomechatronics experts from Ilmenau also built a small robot crawler during the project. The crawler has its tracks to thank for the fact that it can travel up both sloping and flat surfaces without slipping down. The tracks consist of so-called gecko tape, which was developed by biologist Prof. Dr. Stanislav Gorb. The research scientist from the Christian Albrecht University in Kiel (CAU) has been studying the adhesion mechanisms of geckos, spiders and beetles for many years. These creatures have one thing in common: they do not need any glue in order to walk safely across the ceiling. Instead, thousands of small adhesive hairs on their feet provide an incredibly strong grip. The secret behind this adhesive strength consists of attractive forces on the molecular level, which act between the hairs and the surfaces. The inspiration for the gecko tape was provided by the adhesive hairs of some special types of beetle. Under the microscope, they look like mushrooms with a dent in the top. Therefore they work in similar way to suction cups, which further strengthens the molecular adhesive effect.

Together with the company Gottlieb Binder, which specialises in fixing technology, the researchers from Kiel have introduced the gecko tape onto the market. The benefit of the adhesive, which is similar to silicone, is that it adheres equally well to smooth, uneven, slippery and damp surfaces and does not leave any residues behind – so in contrast to traditional adhesive tape it is simple to wash off. This means that it can be reused as often as desired. Even a human being can be hung from the ceiling using the adhesive material, as the researchers have demonstrated themselves.

Spiderman will remain a cinema and comic book hero for now

If you were hoping to crawl over the ceiling like Spiderman in the near future, unfortunately you will have to wait a bit longer. “The smaller the creature, the better it can make use of adhesive effects like these”, explains biomechatronics engineer Hartmut Witte. Larger and heavier creatures need disproportionately more adhesive hairs and stronger adhesive strength in order not only to remain on a surface, but also to detach themselves and stick to it again.

“It was only the fact that pliable mechanisms have been adopted in the area of robotics that has led to the idea of ‘human-friendly robotics’ being taken seriously and put into practice”

Within the household, industry or in the medical area however, the adhesive film could be extremely useful. And in the case of the small robots too, the gecko tape is keeping its promises. In the beginning it was thought that the robot crawler could be used for cleaning solar panels. “In fact, we had already reached agreement with a solar panel manufacturer”, explains Witte. But then the company went bankrupt and the plan had to be put to one side. This is a problem that scientists have to deal with again and again. Universities generally do not have the money or the staff in order to develop a robot up to the production stage. They develop ideas and launch initiatives – which then have to be taken up by industry. If a project partner falls away, a promising idea may have to be shelved. But even if some bionic projects are still waiting for the commercial breakthrough, they have already brought the story of robotics forward on many levels, says Hartmut Witte. Starting with lightweight construction, in other words the development of materials which are based on the light yet stable bone structure or indeed the adhesive powers of small living creatures, up to the use of pliable systems such as those that are used in the elephant’s trunk from Festo. The structure of so-called cobots – collaborative robots which are intended to work hand in hand with humans – would never have been possible without the bionic projects. “It was only the fact that pliable mechanisms have been adopted in the area of robotics that has led to the idea of ‘human-friendly robotics’ being taken seriously and put into practice”, says Witte.

Real time for exoskeletons

The most recent project of the bionics engineers from Ilmenau is also concerned with a robotic system which works very closely with human beings: they are developing an exoskeleton called Leviaktor which is intended to provide support to workers in industry and the trades. Of course such electronic or mechanical lifting aids are not completely new. They already support human beings who are learning to walk again following an accident, or they help workers in industry to lift heavy weights. But the cooperation between man and machine is still not completely smooth and easy.

Some exoskeletons are set up for a specific application or are modified to suit one individual person. If a different person wants to use them, it tends to be difficult, says Witte. “The exoskeletons of today are all reactive.” In other words, they register that the user is pushing in a certain direction, and then follow this with a short delay. The approach of the bionics engineers is to measure the activity of the arm muscles in order to control the supporting movement of the electronic lifting aid. “Muscle physiologists have demonstrated that it is possible to recognise what the muscle is about to do”, explains Witte. By measuring and evaluating the so-called EMG signals, the exoskeleton could anticipate the movements of the human being, instead of only reacting to them, as has been the case up to now.

“If I can find technical solutions, they should not be an additional burden, but must simply fit in with my needs.”

In a project which is set to last three years and is financed by the Federal Ministry of Education and Research to the tune of around 1.5 million euros, the scientists now wish to prove that this process can also prove its worth in practice. The purpose behind it: the greatest possible degree of “biocompatibility”, as Hartmut Witte puts it. “If I can find technical solutions, they should not be an additional burden, but must simply fit in with my needs.” For this is also a central ambition of bionics: to approach and develop technology in such a way that it adapts to we humans – and we no longer have to adapt to technology.

ABOUT

© TU Ilmenau

Hartmut Witte is Professor of Biomechatronics at the Technical University in Ilmenau. With his colleagues and students, Witte – who is also a mechanical engineer and a doctor specialising in anatomy – is concerned with the question of how technical systems can be developed and optimised using biological and medical knowledge.