8 September 2016

The Gotthard Base Tunnel is currently the longest railway tunnel in the world: At over 57 km long, it passes through the central Swiss Alps. Engineers from DMT, a subsidiary of the TÜV NORD GROUP, have been helping out with the precision measurement of the tunnels under the Alps. Its experts are using Gyromat, a high-precision surveying gyroscope, all over the world. DMT project manager Volker Schultheiß reveals in an interview why the measuring device is parked in Qatar and why there is a gyroscope in every plane.

#explore:The breakthrough is an important milestone in the construction of tunnels. Were you present in the Gotthard Tunnel at this special moment?

Volker Schultheiß: We only ever start with our control surveys when the big tunnel boring machine is already about 500 metres deep inside the mountain. We check the tunnelling progress about every kilometre from then on in. The last measurement will usually take place three to five hundred metres before the breakthrough - then we’re done. Projects like the Gotthard Base Tunnel are, of course, an exception. The breakthrough is a major event which is celebrated very much like the actual opening itself. And we’re there too when it happens.

#explore:How keen are you to go through this gigantic tunnel yourself after completion?

Volker Schultheiß: My first big project was the Channel Tunnel between England and France. It was a special moment when I took the train through it a few years later. If I had the chance to go through the Gotthard Tunnel on my way to a holiday destination, that would obviously be great. But I basically close a mental door on a project once I’ve taken the last control measurement. Many of the tunnels that we’re involved are, incidentally, water tunnels - so in any case we don’t get the chance to go in them once they’re finished.

#explore:When is the Gyromat used?

Volker Schultheiß: A gyroscope is needed whenever something has to be precisely aligned that isn’t visible with the naked eye. In practical terms it replaces a compass, which doesn’t work everywhere that steel and iron are used. There are of course many types of gyroscope. They include devices like the Gyromat, which is mainly used in tunnelling and mining, but also in the shipbuilding industry. Today’s big ships are made of steel, and individual parts are put together like a jigsaw puzzle. What you don’t have is a basic structure to provide some orientation. The surveying gyroscope helps place machinery in exactly the right spot in the ship. Gyroscopes are also used for military purposes, for example in the targeting of missiles or submarine building. Gyroscopes which are significantly smaller than the Gyromat are used for orientation purposes in every aircraft.

#explore: The latest model is called Gyromat 5000. How is it possible to improve surveying gyroscopes still further?

Volker Schultheiß: In the 1950s they started developing this kind of gyroscope at DMT. These were very large, very heavy pieces of equipment which needed three or four people to carry them. By the standards of the time the gyroscopes were very accurate, but they would no longer satisfy today's requirements. Over the decades, surveying gyroscopes have become smaller, more manageable and more precise. With the old devices you still had to look through a viewing window, read the data off small wheels and manually calculate the angles yourself. The fully automatic Gyromat 5000 does everything at the touch of button. The measurement data can be downloaded immediately onto a tablet or PC via Bluetooth.

© DMTVolker Schultheiß works around the world and has been to places like China, Russia and Australia and the Middle East area.© Udo GeislerIn front of the south portal of the Gotthard Base Tunnel in the Swiss canton of Ticino: Volker Schultheiß (left) and his colleague prepare the Gyromat for measuring work.© Udo GeislerThe Gyromat surveying gyroscope is needed whenever something has to be precisely aligned that isn’t visible with the naked eye.

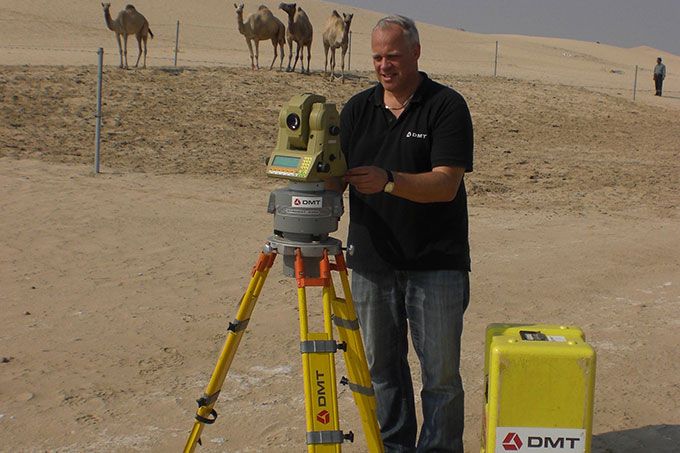

#explore: There are photos showing you at work in the desert with camels behind you. Where have you previously been involved in tunnelling projects?

Volker Schultheiß: We work around the world and have divided up the territories between ourselves. I’ve been to places like China, Russia and Australia but I’m mainly responsible for the Middle East area. For about the last three years I’ve been looking after the control measurements for the underground railway construction work in Doha, the capital of Qatar. I’m also currently working on the Brenner Base Tunnel, the second large tunnel construction project in the Alps.

#explore: How does the Gyromat get from Germany to Qatar?

Volker Schultheiß: The Gyromat is very sensitive and has to be transported in custom-built special boxes that weight 50 kg each. You can’t exactly take them onto the plane as hand luggage. We hire haulage companies that specialise in transporting sensitive goods. In this way the Gyromat gets safely to the construction site. All I have to take with me is my suitcase, since everything else is already in situ.

#explore: How long does the Gyromat’s journey take?

Volker Schultheiß: Sometimes it’s just three or four days, sometimes it takes weeks. The problem isn’t transport but customs. There’s a blacklist of countries into which the Gyromat can’t be imported because it might be used also for military purposes. Which is why we have to check every new foreign order to make sure we’re allowed to take our machine with us in the first place. To reduce the transport time, we’ve parked a Gyromat on almost every continent.

#explore: How does it all look in practice? Do you spend weeks living in hotels?

Volker Schultheiß: No! The great advantage we have is that we only ever come for the control measurements. Surveyors are on site to oversee the tunnelling 24 hours a day, because the big boring machines run continuously without a break. We then check the work of the surveyors at regular intervals. Such jobs usually take 1-2 weeks at most. So what this means in plain language is that I jump from construction site to construction site. If I'm lucky, I might get to spend a week in the office.

© Udo GeislerDMT project manager Volker Schultheiß

#explore:Would you rather be in the office than travelling the world?

Volker Schultheiß: Well, you obviously have to be born for the job. It is of course difficult to be travelling all the time - I spend most of my time sitting in planes or cars, and you also have the constant change of time zones to contend with. That can be very stressful. But on the other hand, it's also great fun.

#explore:What’s fun about it?

Volker Schultheiß: For ordinary people, when you’ve seen one tunnel you’ve seen them all – but to me, every project is a major challenge. After all, to an expert every tunnel is a bit different. If there’s a tunnel with a diameter of 1 metre 50, for instance, I sometimes more-or-less have to crawl through it to do my job. And then, at the other end of the spectrum, you get massive motorway and railway tunnels with a diameter of 14 metres. These are mostly in the mountains where there’s nothing but landscape - in contrast to the underground railway projects in major cities.

YOU MAY ALSO LIKE

THE “GYROSCOPE” PRINCIPLE

© Udo Geisler

Tunnels are made to measure: The plan for the tunnel axis must be followed with the utmost precision to avoid technical problems. But how does a tunnel boring machine deep in the mountain know exactly where to go? The solution is to use a gyroscope. Gyroscopes are based on the physical principle of precession. This describes the change of direction of the axis of a rotating body (a gyroscope) when external forces exert torque on it.

The Earth's gravitational pull as an external force

If such a gyroscope is built into measuring equipment like the Gyromat, the Earth's gravitational pull acts on it as an external force. The gyroscope tries to remain in its original position. If these values can be successfully measured, this kind of gyroscope can be used to determine the direction of the Earth’s axis. Volker Schultheiß and his colleagues can in this way compare the measured data with the planned tunnel data - and get the tunnel boring machine back on course.

The current model is the Gyromat 5000, which, with an angle accuracy of 0.8 mgon (corresponding to a deviation in arc of about 1.2 cm over a distance of one kilometre), is by some margin the most accurate surveying gyroscope in the world.