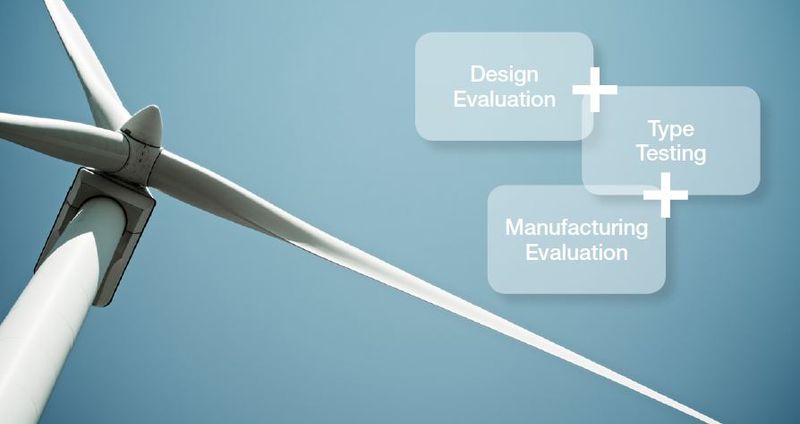

For manufacturers of wind turbine components, TÜV NORD can perform component certification, which would certify the conformity of the relevant component to a chosen standard. The applied procedures as well as the scheme are similar to those within a type certification.

A component certificate can be issued independent to a certain turbine type. Design evaluation is conducted based on design loads. Using loads comparison and other interfaces, the component certification can be implemented into a type certification of the relevant wind turbine on later stage. Most common applications of component certification would be rotor blades, gear boxes or towers.

A component certification offers the following advantages for the manufacturers of wind turbines

Advantages:

- Component certificate can be implemented into various turbine type certificates with minimal efforts

- Component certification timeline can be independent from turbine certification timeline

- Changes in design or manufacturing processes will not directly effects the type certification

- Added value for market entry

For component certification, the design loads should cover all possible turbine loads especially those required for component type testing. In case of higher turbine loads, then a new test might be required. Interfaces such as bolted connections to turbine as well as lightning protection system should be taken into consideration.