FSSC 22000: Saving costs through more efficiency in food safety

Global, complex supply chains and demands for more transparency place high demands on companies in the food sector. With certification according to FSSC 22000 by TÜV NORD CERT, you meet the current challenges of your industry, reduce risks and save costs by using your resources more efficiently.

You make an important contribution to food safety and to combating food fraud and food fraud. With an FSSC 22000 certificate, you position yourself as a company that produces high quality and safely. The standard is recognized by GFSI and accredited by DAkkS. In this way, you strengthen the trust of your customers.

You need help with a certification?

Would you like an offer for a FSSC 22000 certificate?

Benefits of the FSSC 22000 certificate

- Positioning your company as a manufacturer of high quality and safe food or food packaging materials.

- Increased customer satisfaction and confidence

- Reduction of risks in the area of product liability

- Implementation of continuous monitoring of compliance with health and safety regulations

- Integration with other ISO-based management systems possible

- Internationally recognised

FSSC 22000 Version 6: What is new?

Version 6 sets higher requirements for the management of resource efficiency and sustainability for companies that are certified according to FSSC 22000 or are seeking this certification.

Reasons for the revision of FSSC 22000:

- Incorporation of the requirements of ISO 22003-1:2022,

- Strengthening the requirements in the area of sustainability to support organisations in achieving the goals of the United Nations Sustainable Development Goals (SDGs).

- Editorial changes and additions as part of continuous improvement.

- These changes help to make the certification even more understandable and practical.

- FSSC 22000 version 6 was published in April 2023 and is mandatory for all companies from 01 April 2024 - there is a transition period until 31 March 2025, during which time all companies already certified must convert their FSSC 22000 certificates from version 5.1 to 6.

The new requirements relate to the following parts of the standard:

- Use of recycled packaging as raw material (category I)

- Control of special claims on product labels or packaging

- Artwork management and print control (Category I)

- Requirements for suppliers to protect against food fraud (Category FII)

- Cleaning of transport tankers

- Management of foreign bodies

- Ongoing verification of minimum shelf life

- Validation of cooking instructions for "ready-to-cook" products

- More detailed requirements regarding the use of logos, allergen management and environmental monitoring

- Requirements related to food safety and quality culture, quality control, equipment management ("hygienic design"), food losses and waste, and communication requirements (company to certification body)

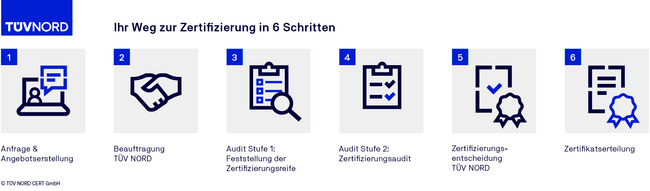

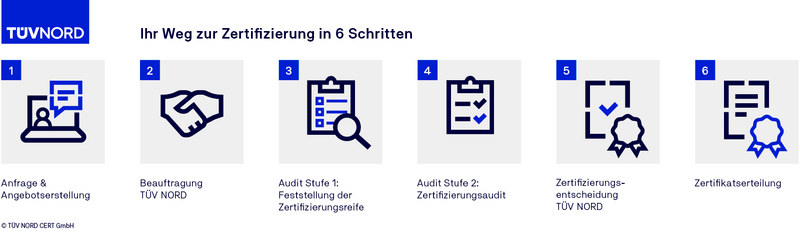

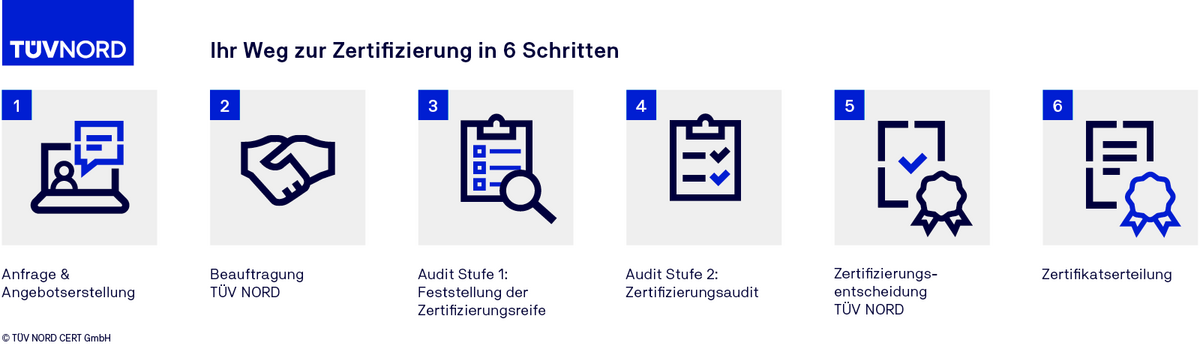

Process of the FSSC 22000 certification

TÜV NORD Whitepaper on Climate Change Integration for FSSC + ISO 22000

Climate Change integration into the standards of FSSC 22000/ ISO 22000

In light of the evolving climate landscape, the standards ISO 22000 and FSSC 22000 must now integrate aspects and risks of climate change into their management systems. This means that climate change should be considered as part of a comprehensive risk assessment to ensure the development, maintenance, and effectiveness of these management systems. Learn more about this crucial update in our latest whitepaper available for download.

Download with restricted access

Frequently asked questions on FSSC 22000

The internationally effective certification system Food Safety System Certification (FSSC 22000) is aimed at companies along the entire supply chain in the food sector. It is now in its 5th version and is based on the DIN EN ISO 22000 standards, the technical specifications for specific preventive programmes for food safety and additional requirements of the standard setter. The standard is recognised by the Global Food Safety Initiative (GFSI).

The FSSC 22000 certification system supports companies with regard to food safety and quality management . Certified companies demonstrate with FSSC 22000 that they meet the requirements and expectations of authorities, business partners and consumers. With FSSC 22000, the companies make a valuable contribution to safety within the supply chain and also internationally.

The certification is suitable for companies of any size that produce, process or package animal or plant products or other food ingredients and additives. Prerequisites are the introduction of a quality management system for food safety as well as the consideration of Good Manufacturing Practice (GMP) and Hazard Analysis Critical Control Points (HACCP). With successful certification, companies have objective proof in their trading partnerships that they have implemented an audited food safety management system.

Elements of the FSSC 22000:

- ISO 22000 as a structuring standard

- PRPs as sector-specific preventive programmes to ensure technical specifications in application

- Additional FSSC 22000 requirements

The catalogue of requirements for FSSC 22000 certification is made up of three elements.

These are:

- The ISO 22000 standard in its current version

- Relevant Preventive Programmes (PRPs), which are based on category-specific technical specifications.

- Additional requirements on the part of FSSC 22000

There are different technical specifications applicable to the different sectors:

- Agriculture: ISO/TS 22002-3,

- Food production: ISO/TS 22002-1:2009

- Manufacture of animal feed: ISO/TS 22002-6:2016

- Catering sector: ISO/TS 22002-2:2013

- Retail/wholesale: BSI/PAS 221:2013

- Storage and transport: NEN/NTA 8069:2016

- Manufacture of packaging materials: ISO/TS 22002-4:2013

In contrast to the pure ISO 22000, the FSSC (Food Safety System Certification) is recognised by the GFSI (Global Food Safety Initiative).

COID stands for Certified Organization Identification Code and refers to the unique identification number that is uniquely assigned to each company certified according to FSSC 22000. The aim of the COID is the unique identification of certified organisations even in the event of a change of certifier and the associated change of certificate number. The COID will be introduced for all certified companies by 31.01.2023 and will be entered in the FSSC Assurance Portal as well as on the certificate.

What changes in Version 6 of the FSSC 22000?

In particular, the requirements for food safety and quality culture (all categories of the food chain) have been formulated in more detail. The obligation of a company is to set, implement and maintain food safety and quality culture targets.

These objectives must relate to the following elements:

- Communication

- Training

- Feedback and engagement of staff

- Performance measurement of defined activities

- Food safety and quality culture plan, including targets and timelines

The quality control requirements (all categories of the food chain) provide for the following:

- Establish, implement and maintain a quality policy and quality objectives.

- Establishment, implementation and maintenance of quality parameters

- analysis and evaluation of the results of the quality control parameters

- Inclusion of these quality elements in the scope of the internal audit

- Establish and implement procedures for quantity control

- Establishing and implementing procedures for the commissioning and conversion of production lines

Equipment management (all categories of the food chain, except FII) requires:

- Documented purchasing specifications for equipment

- Risk-based change management process for equipment

- Evidence of successful commissioning

Food losses and wastage (all categories of the food chain, except I) requires

- Documented policy and targets for food loss and waste reduction strategy.

- Controls to manage product donations

- Management of surplus produce/products destined as animal feed/food

- No compromise on food safety

The communication requirements (all categories of the food chain) include in version 6:

- Organisations must notify their certification body within 3 working days of the onset of a serious event or situation

- Implement appropriate measures as part of their emergency preparedness and response.

- Serious events include war, strikes, terrorism, crime, floods, earthquakes, etc.

- Serious situations include public food safety events, regulatory actions, legal proceedings, and fraudulent activities and corruption

FSSC 22000 certification by TÜV NORD CERT: We make ourselves strong for your company

Objective, neutral, independent: You can rely on TÜV NORD CERT for certifications. You benefit from our many years of experience, our extensive range of certifications and the globally recognised TÜV NORD brand. Our auditors have a wide range of expertise in your industry. Due to annual and comprehensive training courses, their knowledge is always up to date. In this way, they make a decisive contribution to a cost-effective and effective audit. Our interdisciplinary way of thinking and our broad expertise enable us to offer you sensible combinations in the area of certification from a single source, for example in the area of FSSC 22000 and ISO 9001.

Your international sales contact in Germany

TÜV NORD CERT GmbH

Food & Agriculture

Tel.: +49 (0)160 888 3919

Food-Certification@tuv-nord.com

International Sales Contact by Country

CCPB Italy

Mrs. Elisabetty Szulin

eszulin@tuv-nord.com

Tel: +39 (0)3701300804